Category

China Jinhong KN95 Mask Making Machine

JH-KZ60 N95 Machine Instruction:Equipment overview and composition This fully automatic production line is for producing

Basic Info

| Application | KN95 N95 Mask, Medical |

| Automatic Grade | Automatic |

| Certification | CE |

| Customized | Non-Customized |

| Condition | New |

| Material | Stainless Steel |

| Logo Printing | Without Logo Printing |

| Recycled | Unrecycled |

| Flexibility | Hard |

| Technics | Offset Printing |

| Type | Complated Set |

| Transport Package | Wooden Cases |

Product Description

JH-KZ60 N95

| Compatibility | Only one type of N95 mask can be produced by this machine |

| Total Power | 16kw |

| Air Supply | 0.5MP-0.8MP,flux:290L/Min |

| Capacity | 30-50 pcs/minute |

Using Environment | The temperature is 10-35ºC, the humidity is 5-35%HR.The ground load is less than or equal to 500kg/m2,there is n flammable, corrosive gas, the cleanliness is not less than 100,000 dust free workshop. |

| Net Weight | ≤4500KG |

Total Amount | FOB China Date Of The Price has one week Validity |

| Payment Term | T/T 50% before production for deposit. T/T 50% before shipment |

| Delivery Time | Within 20 workingdays after receiving the production deposit |

Warryanty | 1 year warranty |

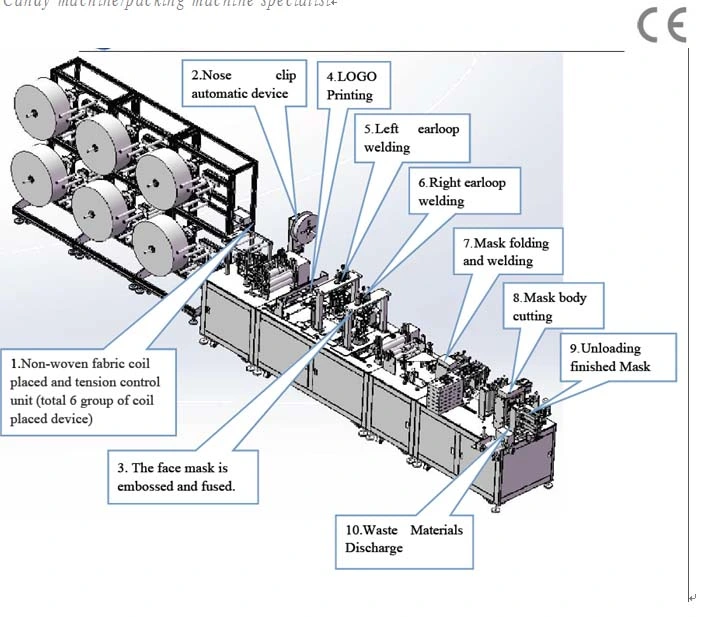

Machine Instruction:Equipment overview and composition

This fully automatic production line is for producing N95 series folding masks, which composes the raw material cloth roll feed, nose line welding, mask surface welding, automatic body cutting, logo printing, valve hole punching cutting (optional), breathing valve installation (optional), body cutting, earloop welding, main body forming, main body fusing and blanking of finished products. The equipment will not cause any damage to the filtering performance of raw materials during operation. The filtering effect of N95 masks produced by this equipment up to the international N95 standard.

The equipment is mainly composed of the following parts:

- Non-woven fabric roll placement and tension control unit (a total of 6 roll placement devices)

- Automatic cloth deviation correction unit (optional)

- Non-woven composite rolling unit:

- Mask nose clip assembly unit:

- Mask surface pattern welding unit:

The pressure of the welding system is adjustable. The ultrasonic working program is controlled by a PLC connected to the host. The system of welding or knurling wheels can be operated on the touch screen. Wheels is controlled by the opening and closing of the cylinder, and the compression gap can be adjusted.

- Character printing unit (this item is optional):

- Ear strap assembly unit:

fiber. The ultrasonic welding process is used for connecting and sticking earloop and the mask body. The knitted belt is completely welded without defects of desoldering, over-welding, and virtual welding.

- Body cutting and waste discharging unit:

- Breath valve assembly unit (this unit is an optional unit, the unit is not included in the standard configuration):

- Folding forming unit:

- Nose and forehead welding unit:

- Forming and cutting unit:

- waste separation unit;

- Control system: PLC control system and touch screen operating system.

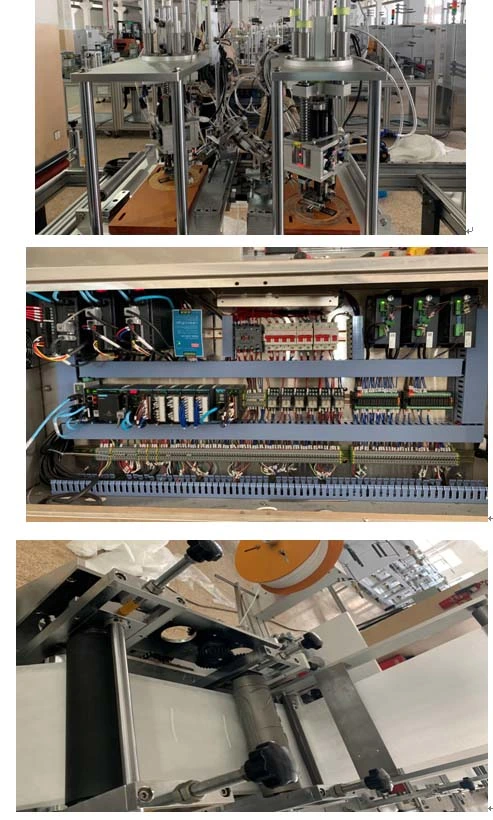

Machine Photos for reference only: