Semi-Automatic Mattress Roll Packing Auxiliary Machinery

Basic Info

| Model NO. | PLCS/PLSS |

| Strapping Material | Plastic Tape |

| Packaging | Cartons |

| Automatic Grade | Automatic |

| Strapping Mode | Welding Type |

| Packaging Material | Plastic |

| Driven Type | Electric |

| Structure | Horizontal Track Strapping |

| Transport Package | by Logestics / by Sea / by Air |

| Specification | ABS/PP/PS/PE/PVC |

| Trademark | POLYSUN |

| Origin | Tongling, Anhui, China |

| Production Capacity | 50000piece/Year |

Packaging & Delivery

Package size per unit product 1100.00cm * 70.00cm * 180.00cm Gross weight per unit product 20.000kgProduct Description

Plastex has strapping machines to suit all applications and all budgets. We offer a full range of fully automatic, automatic, and semi automatic strapping machines that utilize our famous polypropylene strapping. Semi automatic strapping machines are the most economical choice; a great addition to any mail room. The automatic arch machines are extremely reliable and also come in side seal, dual press, small package, and stainless steel configurations. Lastly, our fully automatic arch strappers are for in-line use and require no operator.

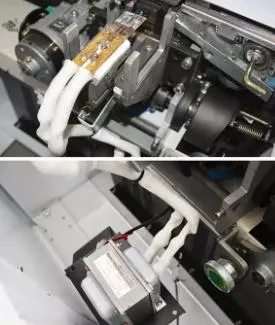

Detailed Photos

| Model No. | PL-201 Fully Automatic PP Strapping Machine |

| Mahchine Dimension | L=1400mm, W=630mm, H=1430mm150 KGS |

| Machine Weight | 150 KGS |

| Width of Strap | 9-15mm |

| Thickness of Strap | 0.55-1.00mm |

| Packing Speed | ≤ 2.5S/Cycle |

Plastex International Trading

Polysun Extrusion MachinePlastex brand was established in 2015. Mr.Yuan, as the owner, has more than 20 years of experience in the plastic extrusion field. They sold more than 100 sets of extruders to overseas counties annually. Plastex extruder passed the ISO9001 Quality Management System Certification and CE certificate.

We aim to sell our products to over the world and dedicate to help humans and the environment harmonious coexistence.Our AdvantagesFAQ

Q:Are you trading company or factory?

A: We are factory with foreign trading department. We manufacture the plastic extruder machine by our own factory. So don't worry about the after-sell servieces.

2.

Q:Where is your factory? How do I get there?

A:Factory address: Xingda Industrial Park, No. 720, North Section of Tongdu Avenue, Tongling City, Anhui Province, China. You cantake a plane to Hefei Xinqiao International Airport or Nanjing Lukou International Airport, we can arrange the pick-up. Or you cantake the high-speed rail to Tongling Station.3.

Q:In what year was your company founded?

A:Our company was founded in 2012, the founder Mr. Yuan Xu has been engaged in plastic machinery and mold processing industry formore than 20 years.4.

Q:What payment methods do you support?

A:We support T/T, Western Union, PayPal and other payment methods.5.

Q:What shipping methods do you support?

A:Sea transportation, air transportation, railway transportation and road transportation, etc. Usually, we go by sea.6.

Q:What is your packaging?

A:Our conventional packaging is: Wrap the plastic film around the machine, and then put the machine in a wooden box.7.

Q:What is your delivery time?

A:Generally speaking, the delivery time of a production line is about 50 days.8.

Q:How is your after-sales service?

A:Our equipment has an 18-month warranty and supports lifetime maintenance. We have a strong technical service team.